Lean Isn’t Old. It’s Misunderstood — And More Essential Than Ever in Modern Manufacturing

Every so often, I meet a leader who tells me, with confidence, “Lean is outdated.” Others insist it doesn’t apply to their industry anymore, or that today’s challenges require something more modern, more digital, more advanced. After three decades leading operations and supporting Lean transformations in manufacturing and healthcare, I’ve come to a very different conclusion: Lean is not outdated. Lean is not a trend. Lean is not something we’ve “moved past.” Lean, when applied correctly and with the right mindset, is more essential today than it has been at any point in the last 30 years.

The reason Lean seems outdated to some is simple: many organizations never actually practiced Lean as it was intended to be practiced. They were exposed only to isolated tools or fragmented training. They tried to copy what Toyota did instead of learning how Toyota thought. They implemented events, not systems. And without the deeper principles underneath, the work never stuck.

Lean endures not because it is old, but because it is rooted in principles that do not expire: respect for people, scientific problem-solving, clarity of purpose, flow-based thinking, and the belief that those closest to the work deserve both the responsibility and the capability to improve it. When organizations rediscover Lean as a way of thinking—not as a toolkit—they rediscover one of the most powerful approaches to operational excellence ever created.

Lean Is a Way of Thinking, Not a Toolkit

One of the biggest misconceptions I still see, especially in manufacturing, is the idea that Lean equals tools. 5S. Kanban. Visual management. Standard work. Value stream mapping. These tools absolutely matter—they help us make problems visible, stabilize processes, and enable flow—but they are not the purpose of Lean. They are simply expressions of deeper thinking.

Lean, at its heart, is a philosophy. It is a disciplined way of seeing work and engaging people. It helps us understand what customers truly value, how work actually happens (not how we assume it happens), and where our systems create friction, waste, and confusion. The tools support the thinking, not the other way around.

When leaders misunderstand this, they chase tools the same way people chase the newest diet trend. They implement the flavor of the month, celebrate for a few weeks, and move on. Nothing changes, because the thinking hasn’t changed. But when leaders use Lean as a lens—when they learn to ask better questions, go see the work, and develop their teams—everything begins to improve.

Why Lean Still Matters in Modern Manufacturing

If anything, Lean is more relevant today than ever. Manufacturing organizations are dealing with challenges that were rare or nonexistent twenty years ago: volatile supply chains, chronic labor shortages, rising customer expectations, increasing customization, and the pressure to do more with less. Technology is advancing at an extraordinary speed, but many manufacturers struggle to translate digital tools into meaningful operational gains.

Lean provides something these organizations desperately need: clarity. Instead of chasing complexity, Lean teaches us to reduce it. Instead of reacting to noise, Lean teaches us to see the signal. Instead of relying on heroics, Lean builds systems that are stable, predictable, and capable of learning.

Lean is not a replacement for modern tools like automation or AI. It is the foundation that makes those investments meaningful. Without disciplined systems and stable processes, technology simply automates chaos.

A Recent Engagement: Real Results from Lean Thinking in Action

Not long ago, I worked with a mid-sized manufacturing organization that had tried almost everything—consultants, software tools, improvement events, leadership programs. Some efforts made incremental gains; others faded within months. The leadership team was skeptical. They didn’t want another “initiative.” They wanted something real—something that would last.

We started the way I always advise: small, focused, and disciplined. Instead of trying to transform the entire plant at once, we selected one model area. This allowed us to learn deeply, test quickly, and build a blueprint for future expansion.

The first step was simple but powerful: direct observation of the current state. Not assumptions. Not reports. Not conference-room discussions. Actual observation of the work as it unfolded.

We asked basic but essential questions:

Where does flow break down?

Where are people waiting unnecessarily?

Which steps are adding real value, and which ones aren’t?

Why is rework happening, and what conditions create it?

These weren’t unfamiliar questions. What was unfamiliar was the methodical way we asked them—and the humility we brought to the process. Leaders set aside their assumptions and made space for learning. Frontline employees shared insights that had never been heard. Together, we began to see the system clearly.

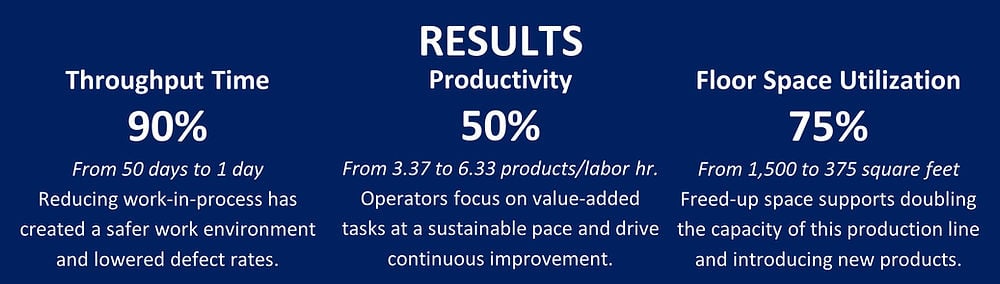

The results were extraordinary:

• 98% reduction in throughput time

• 88% increase in productivity

• 75% reduction in floor space usage

These were not modest improvements. They were transformational. But the numbers only tell part of the story. What really changed was the people. The team didn’t just participate; they led. They generated ideas, tested them, refined them, and took ownership of the improvements. Their confidence grew. Their engagement grew. They saw firsthand that improvement wasn’t something done to them—it was something they could drive.

What Actually Made the Difference?

The dramatic results didn’t come from a big new system or the rollout of every Lean tool in the book. They came from practicing Lean as it was meant to be practiced. Four factors made the biggest impact:

1. Leadership Humility

Humility, in Lean, is not passive. It is active. It is the willingness to say, “I may not be seeing the full picture.” It is choosing to observe rather than assume. It is choosing to ask questions rather than provide answers.

Leaders at this company embraced a posture of learning. They spent time at the gemba. They listened to employees. They were open to discovering that their initial assumptions might be wrong. That humility became the catalyst for improvement.

2. Deep Engagement of the Frontline

In every Lean success story I’ve been part of, frontline involvement is not optional—it’s the engine. Employees closest to the work see the inefficiencies first. They know where the flow breaks. They understand the real constraints.

In this organization, frontline teams were full partners in improvement. They mapped processes. They identified obstacles. They experimented with solutions. Because they created the changes, they sustained the changes.

3. A Methodical, Scientific Approach

Lean is built on cycles of learning. We move from speculation to evidence by testing ideas quickly and evaluating results. At this site, we used Plan-Do-Check-Adjust cycles to implement improvements. We didn’t chase perfection. We chased clarity. We didn’t redesign everything at once. We stabilized processes first, then improved flow, then refined the system.

This steady, disciplined approach built momentum and confidence.

4. A Shift in Mindset—from Fixing Problems to Building Capability

Perhaps the most profound change was in how leaders and teams saw their roles. Improvement wasn’t just about fixing today’s issues. It was about strengthening the system and the people who run it. As capability grew, the pace of improvement accelerated.

This is the true power of Lean: it creates an organization that learns faster than its competitors.

Why Lean Principles Continue to Deliver Results

Lean persists because it is grounded in principles that do not depend on trends, technologies, or industry cycles. These principles remain essential in manufacturing today:

Respect for people—not as a slogan, but as a design principle for how work is structured

Value defined by the customer

Waste elimination as a daily habit

Flow-based thinking to reduce delays and variability

Scientific problem-solving grounded in evidence

Leader standard work that reinforces learning and stability

When these principles guide the work, organizations thrive.

Lean Is Not a Cost-Cutting Strategy

Too often, Lean is misused as a tool to reduce headcount. That interpretation is not only incorrect—it is destructive. Lean was never intended to be a mechanism for cutting labor costs. It is a system for growing capability, unlocking creativity, and improving performance through people.

In the example above, productivity rose dramatically—not because jobs were eliminated, but because the team learned to perform their work with greater clarity, flow, and purpose. Lean didn’t reduce the workforce; Lean elevated the workforce.

What This Means for Manufacturing Leaders Today

If you’re leading in manufacturing—whether a plant, a department, or a team—now is the time to revisit the fundamentals. Not because Lean will magically solve every challenge, but because Lean provides the framework to understand those challenges and address them systematically.

Ask yourself:

Are we solving real problems, or just reacting to symptoms?

Do we have stable, repeatable processes—or do we depend on heroics?

Are our frontline employees engaged as thinkers, not just doers?

Are our leaders modeling humility, curiosity, and disciplined learning?

Do we practice Lean as a system, or as a scattered set of tools?

These questions reveal more about organizational health than any dashboard ever could.

Lean Is Not a Shortcut—But It Is a Path Worth Walking

Lean is not the fastest path. It is not the flashiest. It is not the trend that executives brag about for six months before moving on to something new. Lean is a discipline—a way of thinking and leading that transforms cultures, operations, and outcomes.

In my experience, Lean remains the most powerful, practical, human-centered system for improving manufacturing performance available today. It works not because it is old, but because it is true. It works because it honors people. It works because it aligns purpose with process. It works because it builds capability, not dependency.

Lean isn’t outdated. Lean is a competitive advantage hiding in plain sight. And for the organizations willing to practice it with humility, rigor, and authenticity, it continues to deliver results that matter—results that sustain, results that transform, and results that remind us what people and systems can achieve when they improve together.

Comments