From Conference Rooms to Accountability Boards: Evolving Meetings in Lean Management

In the early 2000s, I worked at Steelcase, moving between roles as a Value Stream Manager and a coach within the Steelcase Production System (SPS) office. Part of my role involved defining, implementing, and coaching teams on Lean practices. One of the areas that consistently surfaced as a challenge was operations meetings.

At that time, most meetings took place in conference rooms. People would gather, sometimes late, sit around a table, discuss issues, and occasionally take notes. Outcomes were often unclear: Who was supposed to take action? By when? And would anyone follow up? In essence, Rules 1 and 2 of Lean communication—clarity of activity and clarity of communication—were routinely violated. Something had to change.

The Problem With Traditional Meetings

Traditional meetings, especially in large operations, tend to create inefficiency rather than solve problems. Even when participants are engaged, the structure often inhibits accountability. Common challenges include:

- Unclear Ownership: Decisions are discussed, but no one is explicitly assigned responsibility.

- Delayed Follow-Up: Without a visible record, actions are forgotten or delayed.

- Time Waste: Discussions can wander, consuming time without producing tangible results.

- Lack of Engagement: Sitting around a conference table can make meetings passive rather than active.

During my time at Steelcase, I noticed these patterns repeatedly. Operations leaders needed a system that would make meetings faster, more effective, and more aligned with Lean principles.

Experimenting on the Floor

Together with my supervisors from the storage assembly lines, we began experimenting with a different approach. We moved meetings out of the conference room and onto the floor—literally to the area where work was happening. These were now stand-up meetings, quick huddles where everyone could see the work and make decisions in real time.

We introduced a physical board to visualize actions, inspired by early Lean thinking and later detailed by David Mann in Creating a Lean Culture. The board became a central element of the meeting: not just a visual aid, but a tool to structure discussions, assign accountability, and track progress.

Defining Simple Rules

The strength of the accountability board lies in its simplicity and clarity. To make it effective, we defined a few clear rules:

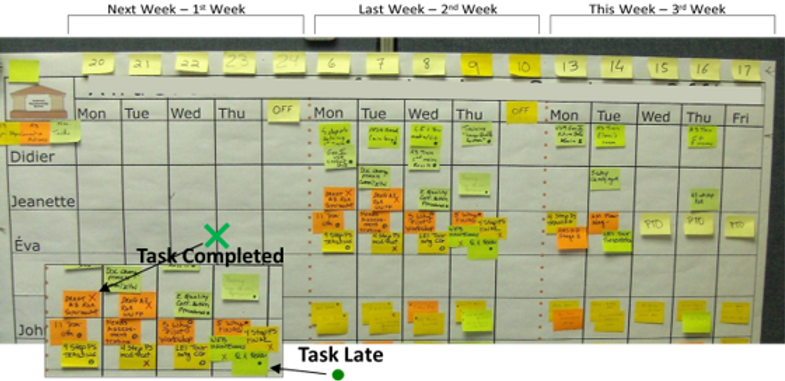

- One Action per Sticky Note: Each task or decision was represented individually. This eliminated confusion and made tracking straightforward.

- Owner-Driven Placement: Only the action owner could place their sticky note on the board. Ownership was visible and unambiguous.

- Carry Original Due Dates: When an action needed to move to a new date, the original due date remained visible. This preserved accountability and historical context.

- Completion Marked Clearly: Completed actions were marked with a green cross, signaling closure.

- Delayed Actions Highlighted: Actions that were behind schedule received a red dot, triggering team support and problem-solving.

- Multi-Week Visibility: The board displayed not only the current week’s actions but also the previous week and the upcoming week. This provided context and allowed for proactive planning.

These rules created a shared understanding among leaders and team members. They ensured that discussions led directly to actionable results and reinforced accountability across the team.

Benefits Observed

Once implemented, the accountability board transformed the way our meetings operated. Some of the key benefits included:

- Efficiency: Stand-up meetings on the floor were faster and more focused. Decisions were made quickly, actions were assigned, and follow-ups were clear.

- Discipline and Role Modeling: Leaders demonstrated accountability and clarity, setting the standard for the rest of the team.

- Improved Follow-Up: With every action visible, it was easier to track progress and provide support where needed.

- Enhanced Engagement: The interactive nature of the board encouraged participation, rather than passive attendance.

Over time, this method proved that a simple visual tool, paired with structured rules, could replace inefficient, time-consuming conference room meetings.

The Accountability Board in Practice

In practice, a typical accountability board session might look like this:

- Review Current Actions: Each owner provides a brief status update. Completed items are marked with a green cross. Delayed items receive a red dot, and the team discusses support needed.

- New Actions: Decisions made during the meeting are captured immediately on stickies, assigned to owners, and placed on the board.

- Forward Planning: Actions scheduled for the next week are reviewed to anticipate resource needs or potential obstacles.

- Quick Problem-Solving: If a sticky remains red, the team engages in a short problem-solving discussion. This prevents delays from lingering and encourages collaborative solutions.

This approach aligns closely with Lean principles: real-time visibility, accountability, problem-solving at the point of work, and clear ownership of outcomes.

Broader Impact on Lean Culture

The introduction of accountability boards was just one step in building a Lean management culture at Steelcase. Over time, I observed several broader impacts:

- Cultural Shift: Leaders and teams began to see meetings as a tool for action rather than discussion for discussion’s sake.

- Increased Transparency: Everyone could see who was responsible for what, and follow-up was visible and verifiable.

- Continuous Improvement: Delayed or blocked actions became opportunities for learning and system improvement.

- Alignment with Lean Principles: The boards reinforced the ideas of visual management, structured problem-solving, and role clarity across levels.

As described in Creating a Lean Culture, the accountability board became a widely recognized and adopted tool in many organizations, extending beyond manufacturing into healthcare, service, and other industries.

Lessons for Modern Organizations

Even 20 years later, the lessons from this experience remain relevant:

- Meet Where the Work Happens: Stand-up meetings on the floor create context and immediacy. Leaders can observe, engage, and make decisions with direct reference to the work itself.

- Visual Management Drives Clarity: A simple board with clear rules creates transparency, reduces confusion, and reinforces accountability.

- Ownership Matters: Assigning clear responsibility and requiring owners to manage their actions prevents ambiguity and follow-up gaps.

- Small Adjustments Have Big Impacts: A simple change in meeting structure and visual tracking can dramatically improve efficiency, engagement, and results.

- Sustainability Through Simplicity: Complicated systems fail. Simple, repeatable, and visible tools encourage adherence and continuous improvement.

These lessons are applicable not only in manufacturing but in healthcare, service operations, and any environment where cross-functional coordination is required.

The Accountability Board as a Lean Management System Element

It is important to remember that the accountability board is only one element of a broader Lean Management System. While effective on its own for improving meetings, it gains maximum impact when integrated with other components, including:

- Daily management and tiered huddles

- Structured problem-solving routines

- Visual management and dashboards

- Standardized work and leader standard work

- Strategy deployment and capability building

When combined, these elements create a system where clarity, accountability, and continuous improvement are embedded in daily operations. The accountability board acts as a focal point for meetings, while the broader system ensures alignment, escalation, and learning.

A Tool Worth Trying

For organizations struggling with traditional meetings, experimenting with an accountability board can provide immediate benefits. The tool is simple, inexpensive, and scalable. It alleviates common pain points: unclear ownership, delayed follow-up, and inefficient discussions.

Even in modern organizations with digital tools and dashboards, the principles of the accountability board remain relevant: visibility, clarity, and ownership. Whether using sticky notes on a physical board or a digital equivalent, the underlying Lean principles do not change.

Closing Thoughts

Reflecting on my time at Steelcase, the evolution from conference-room meetings to stand-up sessions with an accountability board illustrates the power of simplicity and visual management in Lean. Small changes in meeting structure, combined with clear rules and ownership, can produce lasting cultural and operational improvements.

The accountability board is more than a meeting tool—it is a representation of Lean thinking in action. It fosters discipline, role modeling, clarity, and collaboration. It transforms meetings from passive discussions into structured, actionable, and efficient gatherings.

For leaders looking to improve operational performance, the lesson is clear: rethink the way you meet. Focus on visibility, ownership, and real-time problem-solving. Use simple tools that reinforce Lean principles. And remember, even small innovations can have a lasting impact on culture and results.

Comments