Leader Standard Work: The Engine That Drives Lean

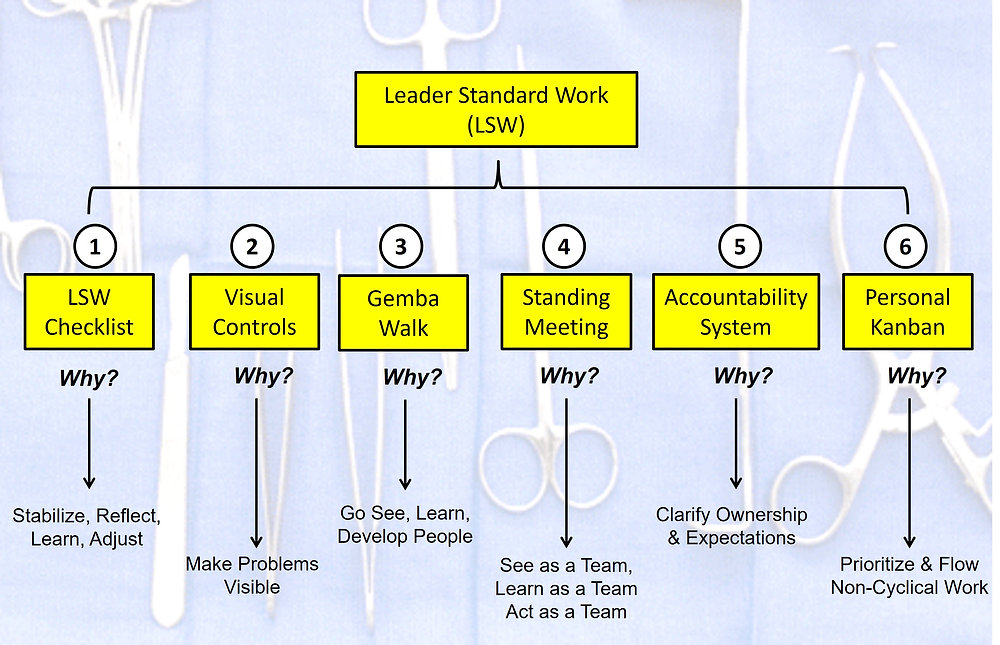

Many organizations think of Leader Standard Work—or LSW—as a checklist. A form. A template to fill out at the end of the day. Too often, LSW is treated like a static document that leaders tick off, a compliance exercise with little connection to real work. That’s the misunderstanding. LSW is not a document. It is a system—a dynamic engine—that stabilizes leadership behavior, exposes gaps, and drives continuous improvement. And like any engine, it only performs when all its parts work together.

LSW is the heartbeat of a Lean leadership system. When fully integrated, it ensures leaders are present at the gemba, visual controls are accurate and actionable, coaching is deliberate and effective, and reflection drives improvement. Without these connections, LSW becomes a piece of paper. With them, it powers performance.

The Engine Analogy

Think of LSW as a high-performance engine. Each component has a role, and isolation weakens the system.

| Car Part | LSW Equivalent | Failure if Isolated |

|---|---|---|

| Engine | LSW document | Runs but goes nowhere |

| Transmission | Gemba walks | No power to process |

| Fuel | Visual controls | Starves the system |

| Ignition | Coaching | No spark of learning |

| Exhaust | Reflection | Builds toxic waste |

Each element is critical. The engine block alone doesn’t move the car. The transmission without fuel stalls. Ignition without spark fails. Exhaust without release builds pressure. LSW behaves the same way: when one component is missing, leadership effectiveness suffers.

LSW Document: The Engine Block

The LSW document is the foundation. It lists tasks, standards, targets, and outputs, giving leaders a structure to guide their day. Here’s a simple example for a plant manager:

| Time | Task | Tool | Std | Actual | Deviation |

|---|---|---|---|---|---|

| 07:00 | Safety Gemba (Line 1) | Board | 10 min | 12 min | +2 |

| 07:30 | Huddle (SQDC review) | Board | 15 min | 14 min | -1 |

| 08:00 | 5S audit (Zone A) | Checklist | 3/5 | 2/5 | -1 |

| 09:00 | Coach 1 problem | A3 | 1 | 1 | 0 |

| 15:00 | Action follow-up | Sticky | 3 | 2 | -1 |

The document provides clarity: what needs to be done, how it will be measured, and where gaps occur. The deviations column triggers reflection and coaching—critical elements that transform data into improvement.

Component 1: Transmission → Gemba Walks

The transmission converts the leader’s intention into action at the floor level. Without it, tasks stay theoretical. The principle is simple: at least 80% of LSW tasks must occur at the gemba—the place where value is created.

Guidelines for Gemba Walks:

- Route: Two fixed paths, 8–12 stops

- Cadence: Daily for supervisors, three times per week for managers, weekly for directors

- Script (3 min/stop):

- See: Read the visual board

- Ask: “What’s red?”

- Coach: “Why?” (5 Whys)

- Act: Assign sticky notes with owner and date

Gemba is not a formality. It is where leaders observe reality, ask questions, and engage directly with the team. Skipping this step disconnects LSW from outcomes.

Component 2: Fuel → Visual Controls

Visuals are the lifeblood of LSW. They communicate expectations, expose deviations, and enable rapid action. Without visual control, even the best LSW template is starved for insight.

Key Visual Controls:

- SQDC board – review at huddle

- Andon lights – respond within 5 minutes

- Action boards – close at least three per day

- 5S maps – audit assigned zones

Rule of thumb: if there is no visual, there is no LSW task. Visuals create transparency and make work visible—two cornerstones of Lean thinking.

Component 3: Ignition → Coaching

Coaching is the spark that turns observation into learning. A leader walking the floor without coaching merely observes; a leader coaching daily develops capability.

Coaching within LSW:

| LSW Task | Coaching Output |

|---|---|

| Coach 1 problem | 1 A3 updated |

| Ask “Why?” | 1 root cause identified |

| Model PDCA | 1 experiment launched |

Coaching Kata (2 min):

- What is the target condition?

- What is the current condition?

- What is the next step?

- When will we see what we learned?

Structured coaching ensures problems are solved systematically, learning is embedded, and employees develop problem-solving skills.

Component 4: Exhaust → Daily Reflection

Reflection is the release valve. Without it, small deviations accumulate into systemic problems. End-of-day reflection allows leaders to review deviations, understand root causes, and plan adjustments.

Daily Reflection Template:

| Time | Tool | Input |

|---|---|---|

| End of shift | 5-min journal | LSW sheet |

Questions to Guide Reflection:

- What deviated?

- Why did it happen?

- What will I change tomorrow?

Weekly reviews consolidate learning: stack LSW sheets, identify Pareto patterns, adjust standards, and refine system flow. Reflection turns execution into improvement.

Full System Flow

When connected properly, LSW becomes a complete engine:

LSW Document → Gemba Walks → Visual Controls → Coaching → Daily Reflection → Improved LSW → Stable Processes → Better Results

Each component feeds the next. Missing a part stalls the engine. Executed together, the system drives sustainable performance gains.

Metrics That Matter

To ensure the LSW engine runs efficiently, track meaningful metrics:

| Level | KPI | Target |

|---|---|---|

| Document | % LSW tasks done | >95% |

| Gemba | % tasks at work | >80% |

| Visual | % boards updated | 100% |

| Coaching | Problems coached/day | 1–3 |

| Reflection | Deviations actioned | 100% |

These metrics align behaviors with outcomes and provide early warning when the system is breaking down.

Launch Sequence (First 30 Days)

Implementing LSW as a system is methodical:

- Week 1: Draft LSW with 80% of tasks at the gemba

- Week 2: Map two routes, install five visual boards

- Week 3: Train coaching kata through role-play

- Week 4: Pilot one leader, audit daily, refine tasks

Small, disciplined steps build habits faster than large, unstructured rollouts.

Real Results from a Six-Month Pilot

| Site | LSW % | Safety | Quality | Delivery |

|---|---|---|---|---|

| Plant A | 96% | -42% incidents | +18% FPY | +11% OTD |

| Plant B | 64% | +11% incidents | -9% FPY | -6% OTD |

Plant A executed LSW as a full system—gemba, visuals, coaching, and reflection. Plant B used LSW in isolation, with minimal gemba engagement and missing visuals, resulting in lower performance.

Common Failures and Fixes

| Symptom | Root Cause | Fix |

|---|---|---|

| LSW = checklist | No gemba | Ensure 80% of tasks at work |

| No deviations | Faked data | Audit randomly, check reality |

| No coaching | “Too busy” | Block 1 hour/day for coaching |

| No reflection | No time | Implement 5-min end-of-day journaling |

These failures are not about effort—they are about system design. When the system is misapplied, results falter.

Your LSW Engine Checklist

- 80% tasks are performed at the gemba

- Visuals at every stop

- 1 coaching kata per day

- 5-min daily reflection

- Weekly Pareto review and standard adjustment

A binder of tasks is useless. LSW must be integrated into observation, visuals, coaching, and reflection to drive real outcomes.

Final Thought

Leader Standard Work is not a form or a spreadsheet. It is the engine of Lean leadership. Properly implemented, it stabilizes behavior, exposes gaps, drives learning, and powers improvement. Without the full system, LSW is scrap paper. With it, LSW ignites a culture of disciplined execution and continuous improvement.

Start the ignition. Align your document, gemba, visuals, coaching, and reflection. Watch your leaders—and your organization—thrive.

Comments