Unlocking Operational Excellence Through Daily Improvement Systems

In today’s operational environment, organizations face relentless pressure to deliver better quality, faster service, and lower costs. Across industries—from manufacturing to healthcare—leaders invest heavily in methodologies, frameworks, and certifications designed to drive improvement. Lean, Six Sigma, TQM, ISO, and High-Reliability Organization (HRO) approaches are all widely adopted. Yet despite these efforts, many organizations struggle to achieve sustainable results.

The missing ingredient is rarely found in the latest framework or technology. The most powerful source of improvement often lies within the organization itself: the ideas, insights, and experiences of its people. Employees at every level interact with processes daily and encounter inefficiencies, risks, and opportunities firsthand. When these insights are systematically captured and acted upon, they can transform ordinary operations into highly reliable, efficient, and innovative systems.

This is where a Daily Improvement System (DIS) becomes essential. It is not a tool or a checklist; it is a cultural and operational framework that empowers employees to identify and implement incremental improvements consistently. By embedding problem-solving and innovation into the daily rhythm of work, organizations can achieve sustained operational excellence.

Why Employee-Led Improvement Matters

Every employee has a unique perspective on how work gets done. Frontline staff see the gaps that technology may not reveal, middle managers understand where process handoffs fail, and leaders recognize strategic misalignments. Tapping into this collective knowledge is more effective than relying exclusively on top-down initiatives.

Empowering employees to contribute is not just about engagement—it is about outcomes. Ideas that originate from those closest to the work are often the simplest, fastest, and most practical solutions. These contributions:

- Reduce waste by identifying non-value-added steps.

- Improve reliability by highlighting error-prone processes.

- Accelerate learning by enabling rapid experimentation and feedback.

- Build ownership and accountability among employees, reinforcing a culture of continuous improvement.

Organizations that fail to leverage this internal potential often invest significant resources in external solutions that fail to address the real problems. A Daily Improvement System ensures that improvement is rooted in what actually happens at the point of work.

What Is a Daily Improvement System?

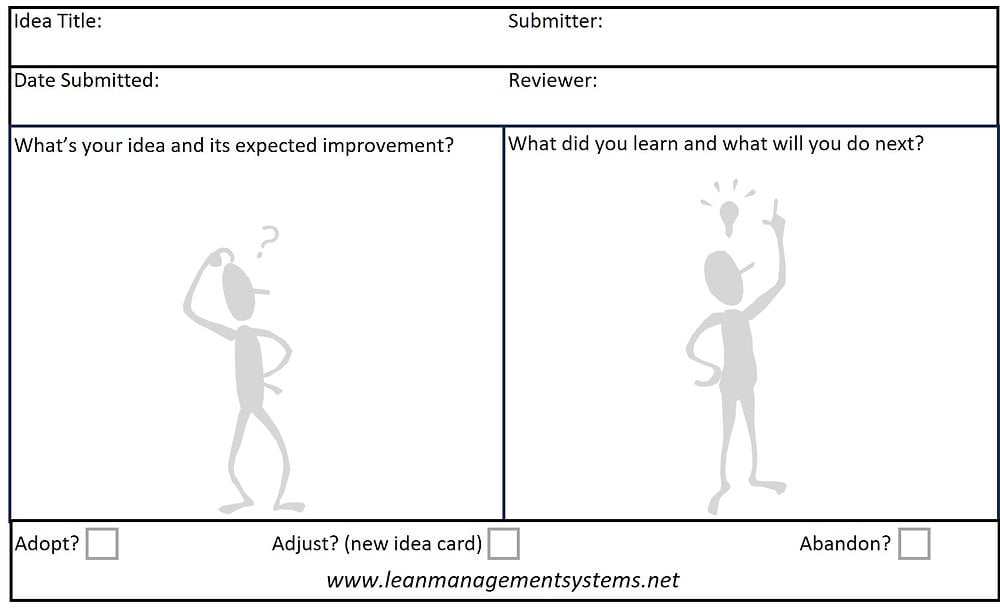

A Daily Improvement System is a structured approach to continuous improvement that encourages employees to share ideas consistently. Unlike large-scale projects or sporadic Kaizen events, a DIS focuses on daily, incremental improvements that accumulate into meaningful operational gains.

Key characteristics of a Daily Improvement System include:

- Regular Contribution: Employees are encouraged to identify and submit improvement ideas every day or every shift.

- Visible Tracking: Suggested improvements are tracked and monitored, ensuring accountability and progress.

- Gemba Support: Leaders engage directly with the workplace to observe processes, coach employees, and facilitate implementation.

- Feedback Loop: Ideas are validated, tested, and refined, creating a system of organizational learning.

- Recognition: Contributions are acknowledged, reinforcing the value of employee engagement and encouraging ongoing participation.

When implemented effectively, a DIS moves beyond suggestion boxes and checklists. It becomes part of the operational rhythm, aligning daily work with strategic goals and customer expectations.

Empowering Employees to Contribute

A core principle of a Daily Improvement System is that every employee can—and should—participate in problem-solving and process improvement. Empowerment begins with creating an environment where suggestions are welcomed and acted upon. Leaders must actively signal that employee insights are valuable and will lead to tangible change.

Practical steps for fostering contribution include:

- Hosting brief daily or weekly improvement huddles.

- Providing multiple channels for idea submission, from digital platforms to physical boards on the shop floor.

- Recognizing contributions publicly to reinforce participation.

- Training employees on problem identification and basic improvement methods to increase the quality of ideas.

Empowering employees is about trust. It communicates that the organization respects their perspective and believes that those closest to the work often hold the best solutions. This mindset strengthens engagement and accelerates improvement.

Supporting Ideas from the Gemba

One of the most effective ways to ensure improvement ideas have impact is through Gemba engagement—leaders observing and supporting the work where it happens. Direct observation allows leaders to see root causes, understand constraints, and provide immediate coaching to refine solutions.

Gemba engagement ensures that improvement ideas are practical and executable. It also fosters a culture of accountability, as employees see that leadership is invested in learning and solving problems alongside them. For example, in a manufacturing line, a worker might suggest rearranging tools to reduce walking time. Observing the process allows the leader to validate the idea, ensure safety standards are met, and share the improvement across the line.

Making Improvement a Daily Habit

Consistency is critical. Improvement cannot be treated as an occasional activity or a one-off project. When employees are encouraged to identify and implement improvements every day, small changes accumulate into meaningful operational gains.

Implementation strategies include:

- Short huddles at the start of each shift to identify potential improvements.

- Allocating a set time daily or weekly for employees to implement or test small improvements.

- Documenting progress on visible boards or digital dashboards to reinforce accountability.

By embedding improvement into daily work, organizations create a self-sustaining system where employees naturally seek ways to enhance processes and outcomes.

Recognizing and Celebrating Contributions

Recognition reinforces the importance of participation. Celebrating even small wins—such as reducing search time for tools, eliminating redundant paperwork, or correcting a recurring error—motivates employees and reinforces a culture of continuous improvement.

Effective recognition strategies include:

- Highlighting contributions in daily or weekly team meetings.

- Featuring success stories in internal communications.

- Providing formal acknowledgment through awards, certificates, or other meaningful recognition.

Celebration is not about ceremony—it is about reinforcing the message that employee ideas matter and have real impact.

Aligning Daily Improvement with Organizational Goals

A Daily Improvement System is most effective when aligned with strategic objectives and customer priorities. Improvement efforts should not be arbitrary; they must connect to outcomes that matter.

- Customer impact: Does the idea improve product quality, delivery time, or service experience?

- Financial impact: Will the improvement reduce cost, waste, or rework?

- Process reliability: Does it reduce errors or variation?

- Strategic alignment: Does it support broader business objectives?

By connecting daily improvements to measurable outcomes, organizations ensure that time and effort are focused on initiatives that truly advance operational performance.

Embedding a Learning System

A Daily Improvement System is more than idea collection—it is a platform for organizational learning. High-performing organizations institutionalize problem-solving and reflection through structured routines:

- Weekly problem review sessions to validate progress, reprioritize, and share lessons.

- Standard work for problem identification to guide employees in selecting high-impact opportunities.

- Knowledge capture in shared repositories to document successful experiments and solutions.

- Leader standard work to ensure consistent engagement with the point of work.

This approach prevents “firefighting” and creates a cycle of continuous learning, ensuring that improvements are sustainable and scalable.

Real-World Examples of Daily Improvement in Action

- Manufacturing: A production line used a Daily Improvement System to address frequent delays. Operators suggested reorganizing tools, adjusting material flow, and implementing a brief shift handover checklist. The cumulative effect reduced cycle time by 15% and improved on-time delivery.

- Healthcare: In a hospital unit, daily huddles captured staff observations about patient flow bottlenecks. Simple changes—such as re-sequencing medication rounds—reduced delays and improved patient satisfaction scores.

- Warehouse Operations: Employees suggested a reorganization of high-volume SKUs based on picking frequency. This small adjustment reduced errors and improved efficiency, demonstrating the compounding impact of incremental improvement.

These examples show that when employees are empowered, supported, and recognized, continuous improvement becomes part of the operational DNA.

Overcoming Common Challenges

Organizations may resist implementing a Daily Improvement System for several reasons:

- “We don’t have time to prioritize improvements.” Prioritizing problems reduces wasted effort and prevents firefighting. One hour spent prioritizing can save ten hours in execution.

- “Everything seems important.” Data and structured frameworks like impact scoring clarify which issues truly affect outcomes.

- “Leadership wants quick wins.” Quick fixes often address low-impact issues. A focus on meaningful improvements builds credibility and trust.

Addressing these challenges requires leadership commitment, clear communication, and consistent routines that reinforce the value of employee-led improvement.

Taking Action: Implementing Your Daily Improvement System

- Start small: Identify three recurring issues and apply an impact filter to prioritize them.

- Validate: Observe processes, collect data, and confirm the real causes.

- Act: Implement small, testable improvements using structured methods like A3 problem-solving.

- Review: Track progress, celebrate wins, and adjust priorities monthly.

- Scale: Extend the system across teams, departments, or facilities once the process proves effective.

By starting with focused steps and building routines, organizations can embed a culture of continuous improvement that grows over time.

The Leadership Mindset

Daily Improvement Systems are not about doing more work—they are about doing the right work. Leaders who embrace this approach focus on enabling their teams to identify and solve meaningful problems. Their legacy is measured not by activity but by the capacity they build in their people, the value they protect for customers, and the efficiency they create in processes.

Leaders who engage consistently at the Gemba, reinforce learning, and recognize contributions create a self-sustaining system of operational excellence. Daily improvements become a habit, learning accelerates, and innovation emerges naturally.

Key Takeaways

- Employee insights are a powerful source of improvement; organizations don’t need to look outside to innovate.

- Small, daily improvements compound into substantial operational gains.

- Gemba engagement ensures that improvements are practical, tested, and aligned with operational realities.

- Recognition and feedback reinforce participation and strengthen culture.

- Structured systems connect daily improvements to strategy, customer outcomes, and financial impact.

By leveraging the ideas already present in the workforce and creating routines to capture, validate, and implement them, organizations can achieve continuous improvement, operational reliability, and sustainable excellence.

Comments