Plan Versus Actual (PVA) Boards: Turning Visibility into Operational Excellence

In organizations striving for operational excellence, clarity and visibility into performance are critical. Leaders and teams cannot manage what they cannot see. Understanding whether objectives are being met, how current performance compares to planned outcomes, and where deviations exist is essential to maintain flow, reduce waste, and drive consistent improvement. Without real-time insight, minor issues can escalate into systemic problems, leading to inefficiencies, missed targets, and frustration for both staff and customers.

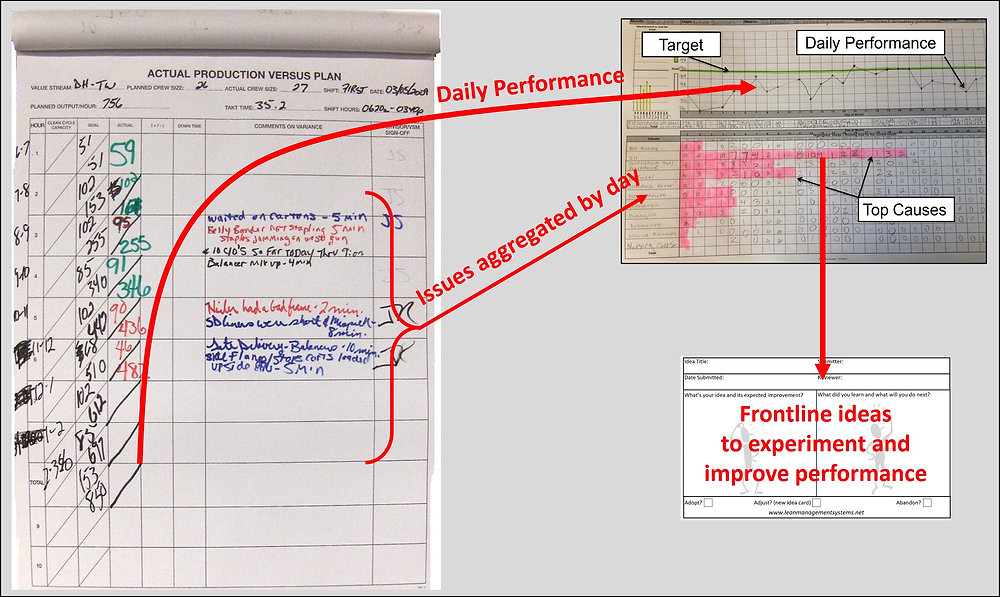

A Plan Versus Actual (PVA) board is a visual management tool designed to bridge this gap. It provides a continuous, transparent view of performance, enabling teams to identify variances immediately, take corrective action, and learn from outcomes. When leveraged effectively, a PVA board becomes more than a tracking device—it becomes a behavioral and operational lever that drives accountability, collaboration, and sustained improvement across the organization.

Why Real-Time Visibility Matters

Traditional reporting often relies on daily, weekly, or monthly summaries. While these reports provide a high-level view, they are rarely sufficient for operational control. Waiting for end-of-day reports or weekly summaries means issues are often detected too late, creating reactive firefighting and eroding performance.

PVA boards address this problem by providing real-time visibility. Teams can immediately compare planned performance against actual results, enabling rapid adjustments. Whether reallocating resources, adjusting schedules, or troubleshooting bottlenecks, timely insight allows organizations to prevent small deviations from compounding into larger systemic problems.

High-performing organizations treat PVA boards as dynamic tools, not static charts. Teams actively interact with the board, prioritize issues collaboratively, and leverage the insights to drive problem-solving. This engagement ensures performance is transparent, actionable, and aligned with organizational objectives, turning data into insight, and insight into action.

PVA Boards as a Catalyst for Team Performance

A PVA board is not just a performance monitor. It is a mechanism that shapes behavior, encourages collaboration, and embeds continuous improvement into daily routines. By comparing planned objectives to actual outcomes, a PVA board enables teams to:

- Detect deviations early: Problems are visible as they occur, allowing teams to act before issues escalate.

- Prioritize high-impact challenges: Resources can be directed to the areas that will produce the greatest operational benefit.

- Encourage collaboration: Teams analyze discrepancies together, identify root causes, and develop solutions.

- Foster continuous improvement: Insights from the board drive learning, experimentation, and enhancements to processes.

When the board is updated frequently—ideally hourly—teams create a continuous feedback loop, where performance is monitored and improved in real-time. The board becomes a living system that guides decision-making rather than a passive display of numbers.

Understanding the Plan Versus Actual Board

At its core, a PVA board is a visual management system that shows planned versus actual performance for key operational metrics. By presenting this information in a clear, accessible format, it allows teams to quickly identify gaps, understand the impact of deviations, and focus efforts on improvement.

Core features of an effective PVA board include:

- Real-time updates: Data is refreshed regularly, reflecting the latest performance conditions.

- Clear visual indicators: Colors, symbols, or charts immediately highlight variances between plan and actual.

- Accessible location: The board is placed where the team can interact with it throughout the day.

- Integration with problem-solving: The board is used to drive discussions about corrective action, improvement, and accountability.

When implemented properly, a PVA board shifts focus from reactive firefighting to proactive problem-solving, ensuring teams are engaged in real-time improvement rather than simply monitoring performance.

Tips for Effective PVA Board Use

1. Real-Time Tracking

Why it matters:

The faster a team identifies a gap between plan and actual performance, the faster corrective actions can be taken. Without real-time tracking, small deviations can grow into systemic inefficiencies, impacting productivity, quality, and customer satisfaction.

How to implement:

- Update the PVA board hourly or at defined intervals.

- Assign responsibility for accurate data entry and verification.

- Use color-coding to indicate performance status (green = on target, yellow = minor deviation, red = off target).

Example:

A production line tracks output versus target on an hourly PVA board. When one workstation falls behind, the team reallocates resources immediately, maintaining overall flow and preventing downstream delays.

2. End-of-Day Analysis

Why it matters:

Hourly updates address immediate gaps, but end-of-day reviews reveal trends and systemic issues. This level of insight helps differentiate isolated incidents from recurring problems that require deeper intervention.

How to implement:

- Compile the day’s PVA data for review at the end of each shift.

- Visualize trends using charts or graphs.

- Apply Pareto analysis to focus on the few issues causing the majority of deviations.

- Discuss findings in team meetings to ensure learning and accountability.

Example:

A logistics center discovered that late deliveries were repeatedly linked to a single bottleneck in order picking. Addressing this systemic issue improved throughput for the following week.

3. Collaboration and Innovation

Why it matters:

A PVA board is more than a performance monitor; it is a platform for team collaboration and innovation. Reviewing discrepancies together fosters brainstorming, testing new approaches, and continuous improvement.

How to implement:

- Encourage teams to collectively review deviations and propose corrective actions.

- Test small process changes informed by PVA insights.

- Document successful interventions and incorporate them into standard work.

- Celebrate improvements to reinforce a culture of continuous learning.

Example:

In a manufacturing facility, repeated downtime on a key machine prompted a team discussion during the PVA review. Rotating operators and adjusting preventive maintenance schedules led to measurable improvements in uptime and productivity.

Avoiding Common Pitfalls

Even a well-designed PVA board can fail if not used correctly. Common mistakes include:

- Treating the board as a passive display rather than an interactive tool.

- Updating data infrequently, which reduces timeliness and relevance.

- Ignoring end-of-day analysis, which misses systemic improvement opportunities.

- Failing to assign accountability, leaving deviations unresolved.

Avoiding these pitfalls ensures the PVA board drives real operational excellence rather than merely showing numbers.

Measuring the Impact of PVA Boards

Organizations that consistently leverage PVA boards report tangible improvements:

- Operational performance: Real-time monitoring ensures targets are met and delays are minimized.

- Accountability: Visible performance data motivates teams to own results.

- Problem-solving capability: Regular discussion and analysis sharpen critical thinking and continuous improvement skills.

- Cross-functional collaboration: Teams break down silos and work together to resolve issues.

Key metrics to track include:

- Frequency and accuracy of PVA updates

- Number and resolution of deviations in real-time

- Response time to issues

- Improvements in KPIs such as output, quality, and on-time delivery

Integrating PVA Boards into a Lean Management System

A PVA board reaches its full potential when embedded in a broader Lean management system. Key integrations include:

- Leader Standard Work (LSW): Leaders use the board to coach teams, monitor performance, and reinforce improvement behaviors.

- Daily Huddles: Incorporate PVA review into team meetings to ensure alignment and accountability.

- Visual Management Systems: Combine PVA boards with huddle boards, process metrics, and KPI dashboards.

- Structured Problem-Solving: Use insights from the PVA board to guide root cause analysis, experimentation, and process improvements.

By embedding the board into daily routines, organizations create a continuous feedback loop that links planning, execution, and improvement in real-time.

Conclusion: PVA Boards as a Performance Catalyst

A Plan Versus Actual board is far more than a visual tracking tool. When used effectively, it becomes a strategic enabler that:

- Detects and corrects deviations quickly

- Prioritizes high-impact issues

- Encourages cross-functional problem-solving

- Embeds learning into standard work

- Drives sustained improvement and accountability

Organizations that embrace PVA boards as dynamic, interactive tools—not just static displays—see measurable improvements in performance, engagement, and operational effectiveness.

Action Steps: Implementing or Enhancing a PVA Board

- Assess Current Practices: Determine whether your team tracks performance in real-time and proactively identifies deviations.

- Design the PVA Board: Define key metrics, update frequency, visual format, and placement for maximum visibility.

- Integrate into Daily Routines: Use the board for hourly updates, end-of-day review, and collaborative problem-solving.

- Assign Roles and Responsibilities: Ensure accountability for monitoring, updating, and acting on deviations.

- Measure and Improve: Track performance improvements, refine metrics, and continuously adapt processes to maximize impact.

By following these steps, a simple visual tool becomes a powerful engine for operational excellence, creating an environment where teams see the work, solve problems proactively, and continuously improve.

Comments