From Crumpled Systems to Elegant Operations: How Lean Thinking Shapes High-Performance Organizations

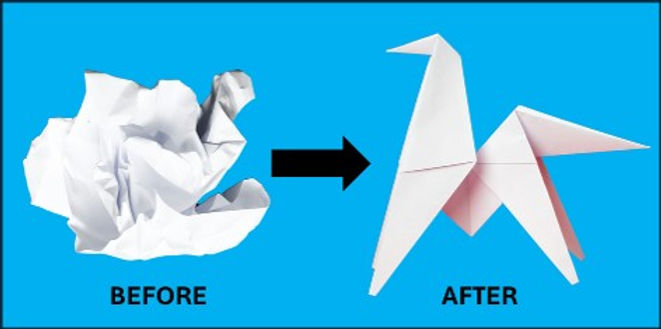

When I look at the image of a crumpled sheet of paper beside an intricate origami shape, I see one of the most powerful metaphors for organizational transformation. At first glance, both objects are simply paper. One is wrinkled, bent, and without form. The other is intentional, structured, and full of purpose. Both contain the same raw potential. What differs is the way the material has been shaped.

Across industries, I encounter organizations that operate like that crumpled sheet. The people are capable. The assets are in place. The intent is good. Yet the systems that guide the work are filled with friction and waste. Teams rely on heroic effort rather than predictable flow. Leaders spend their time firefighting instead of coaching. Results are achieved, but at great cost—fatigue, rework, frustration, and underperformance.

But systems that feel chaotic or inefficient are rarely broken beyond repair. They are simply waiting to be unfolded, examined, and refolded with intention. This is the essence of Lean and continuous improvement: taking what already exists and reshaping it into something far more elegant, efficient, and aligned.

Lean transformation is not about adding complexity or layering in new initiatives. It is about revealing potential that is already present—just hidden under the wrinkles of unclear processes, inconsistent routines, and unaligned goals. With the right approach and leadership commitment, even the most tangled systems can be reshaped into high-performance operations that work smoothly and empower people at every level.

This article explores how organizations can move from crumpled processes to structured excellence by applying Lean principles through three essential steps: identifying what is not working, straightening out inefficiencies, and redesigning systems for long-term success. This transformation mirrors the art of origami—turning something simple and imperfect into something precise and purposeful.

Seeing the Wrinkles: Understanding What Isn’t Working

Every improvement journey begins with seeing the current state clearly. A crumpled sheet of paper doesn’t look chaotic because it chose to be that way; it simply has not been unfolded and examined. The same is true for organizational systems. Processes accumulate unnecessary steps over time. Workarounds replace standard work. Leadership expectations drift. Communication becomes inconsistent. People adapt to the environment around them, even when that environment is full of waste.

Teams often operate within these conditions without fully recognizing the degree of friction they absorb every day. The organization becomes accustomed to delays, breakdowns, or repeated problems. Progress slows even as effort increases.

The first step—the Lean step—is to ask the right questions at the right depth.

What recurring challenges consume time and energy?

Where do delays, rework, or ambiguity show up?

Which patterns repeat week after week despite best intentions?

What assumptions limit possibilities for change?

Uncovering these conditions requires more than process mapping or dashboard analysis. It requires presence at the point of work. It requires leaders to listen carefully without judgment. It requires slowing down long enough to see the difference between symptoms and causes.

In many organizations, the source of frustration is not a lack of effort. It is a lack of clarity. Teams experience conflict or inefficiency because expectations are not shared, processes are not standardized, and decisions are not made close to the work. The crumpled texture of the system hides potential, just as folds and creases hide the surface of a sheet of paper.

When leaders take the time to see these wrinkles—without blame—they open the door to meaningful improvement.

Straightening Out Inefficiencies: Aligning Systems and Removing Waste

Once the wrinkles are visible, the next step is to straighten them out. This is where Lean thinking provides structure and discipline. Straightening out inefficiencies is not about quick fixes or shortcuts. It is about separating what adds value from what does not, and then having the courage to remove or realign what gets in the way.

This phase focuses on reducing friction by clarifying expectations, improving flow, and creating consistency across teams and processes.

Waste shows up in many forms: unnecessary movement, unclear responsibilities, overprocessing, waiting, or rework. Organizations often tolerate these conditions for years because they do not appear catastrophic. Yet they slowly drain energy, attention, and resources. Smoothing out these inefficiencies is similar to flattening the creases in a sheet of paper—it allows the material to take on a new shape with far greater precision.

Consider the example of a manufacturing team facing frequent production delays. Their equipment was capable. Their workforce was skilled. Yet performance remained unstable. A closer look revealed a changeover process that varied significantly depending on who performed it. Without a standardized sequence and clear roles, each shift improvising their own approach. By establishing a structured quick-change process based on Lean principles, the team reduced downtime, stabilized flow, and increased productivity—all without adding cost.

This kind of improvement happens only when leaders and teams commit to examining their processes with humility and curiosity. Straightening out inefficiencies is not about removing people. It is about removing obstacles so people can do their best work.

When organizations take this step seriously, friction decreases. Communication becomes more direct. Problems surface earlier. Work becomes more predictable. The system starts to move from crumpled to clear.

Folding with Purpose: Designing Systems for Long-Term Excellence

Once the system is clear and aligned, leaders can begin the most strategic work: folding with purpose. Just as origami requires intentional design, organizational transformation requires disciplined system design. With a clean sheet—one where inefficiencies have been addressed—leaders can shape processes that reinforce the organization’s goals and values.

This is the stage where organizations define operating systems that are resilient, aligned, and sustainable.

A resilient operating system is built to withstand the inevitable pressures of growth, turnover, complexity, and uncertainty. It does not rely on individual heroics. Instead, it rests on clear standards, visual systems, and well-developed problem-solving capability at every level.

An aligned operating system ensures that every part of the organization—from strategy to daily work—moves in the same direction. Teams understand not only their tasks, but the purpose behind them. Leaders connect daily activities to strategic objectives. Priorities are not left to interpretation; they are reinforced through routines, communication patterns, and shared expectations.

A sustainable operating system is one that persists beyond the presence of a single leader or consultant. Improvements become embedded in daily habits. Learning becomes part of how work is done. Accountability is built into the structure, not dependent on reminders or pressure.

Consider a healthcare organization struggling with inconsistent patient discharge processes. Nurses were often rushed at the end of shifts. Communication between disciplines was uncoordinated. Families received different instructions depending on who was on duty. By redesigning the standard work and implementing a daily management system, the organization established predictable routines that improved clarity, safety, and throughput. The results were measurable: faster discharge times, fewer errors, and a more coordinated experience for patients and staff.

This is the power of folding with purpose. It transforms a once-crumpled process into a reliable, elegant system that delivers better outcomes every day.

Transformation Requires Commitment, But the Results Endure

Moving from a crumpled system to structured excellence is not a one-day event. It is not accomplished through training alone or by adding new software, automation, or dashboards. It requires leaders who support learning, teams willing to challenge assumptions, and a culture that values continuous improvement over static comfort.

Transformation becomes possible when organizations develop a shared belief that their systems can change—and that improvement is everyone’s responsibility.

Leaders who thrive in this environment demonstrate a few core behaviors. They go to the point of work to understand reality. They ask questions instead of giving orders. They listen with intention. They reinforce standards consistently. They make problems visible, not personal. Most importantly, they support teams as they experiment, learn, and grow.

When organizations embrace this mindset, the outcomes extend far beyond efficiency. Employees feel valued because they are invited to participate in shaping the system. Communication becomes clearer and more constructive. Customers experience greater reliability and quality. Leaders spend less time firefighting and more time developing capability. The entire organization becomes more adaptive, more confident, and more aligned.

What Is Your Crumpled Process?

Every organization, no matter how mature, has at least one process that feels like a crumpled sheet of paper—functional but far from ideal. It may be a scheduling routine, a discharge process, a maintenance workflow, a procurement cycle, or a customer onboarding sequence. These processes drain energy and create avoidable frustration, but they are also opportunities waiting to be unfolded.

The first step is simply to acknowledge that improvement is possible. The next step is to explore what keeps the process crumpled and what it might look like if redesigned with purpose.

If you can identify even one process that needs attention, you already have a starting point for transformation.

Ready to Unfold New Possibilities?

If your organization is ready to bring clarity, simplicity, and elegance to its processes, the journey begins with seeing the reality, straightening the inefficiencies, and redesigning with purpose. Whether you operate in manufacturing, healthcare, or service industries, the principles remain the same. Potential exists in every system. The question is whether the organization is willing to unfold the paper and reshape it into something exceptional.

If you are ready to explore that possibility, let’s start the conversation.

Comments